Last Updated on January 3, 2026

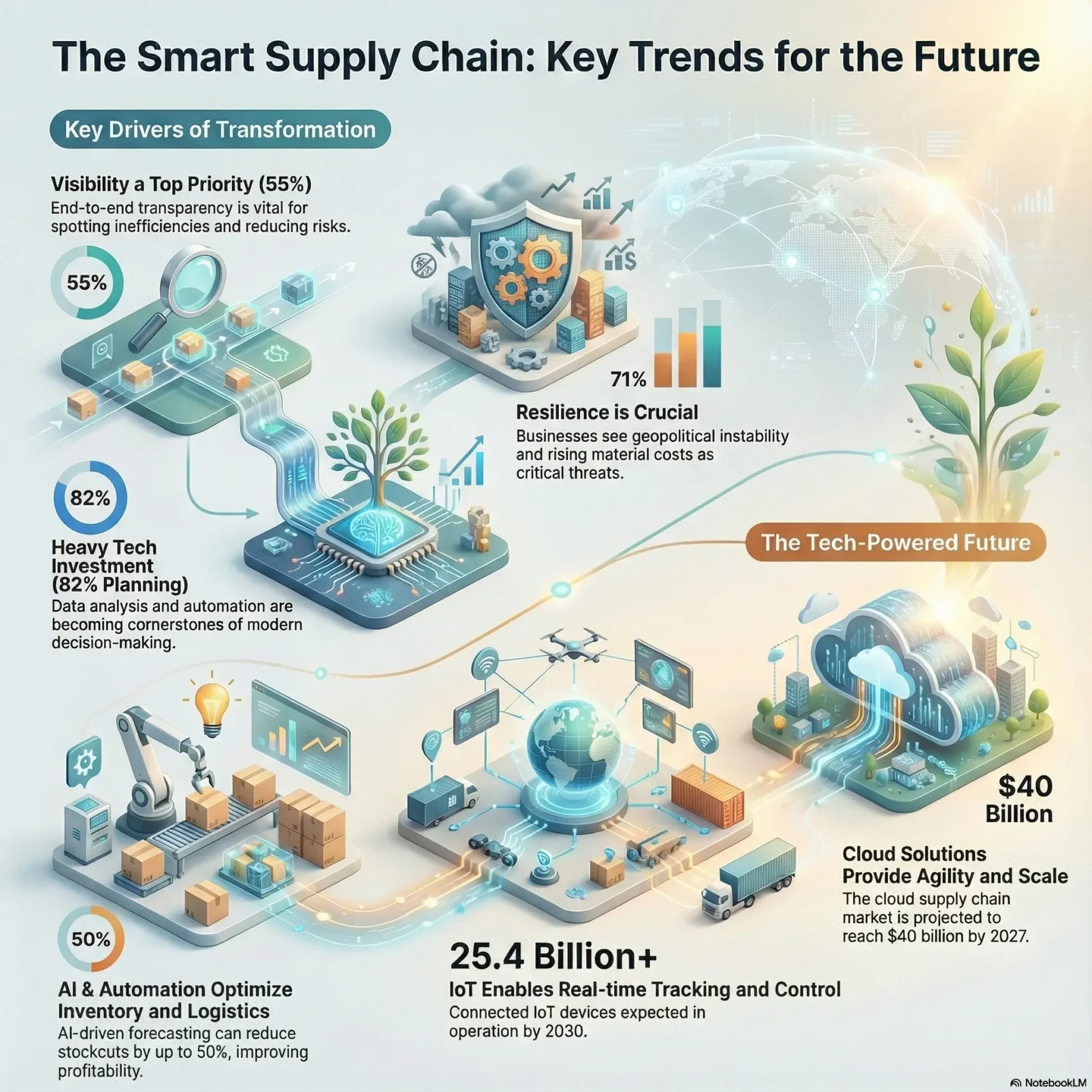

The landscape of supply chain management is undergoing a significant transformation. As we look to the future, it’s crucial to grasp how technological advancements and shifts in consumer expectations are reshaping this field. Recent studies indicate that 82% of procurement leaders intend to invest heavily in technology over the next five years. By 2024, data analysis is set to become a cornerstone of decision-making, underscoring the pressing need for embracing new supply chain trends.

Collaboration between suppliers and buyers will become increasingly crucial for sustainability and efficiency in the evolving supply chain. As we navigate the trends of 2023, remember that human expertise remains paramount, even with technological progress. Adopting trends like process automation and agile management will be key to overcoming uncertainties and seizing new opportunities.

Key Takeaways

- Significant investment in technology is expected among procurement leaders.

- Data analysis will take center stage in decision-making by 2024.

- Collaboration in the supply chain ecosystem will be essential for success.

- Human capital remains crucial despite advancements in technology.

- Process automation and agile management will shape supply chain strategies.

The Evolving Landscape of Supply Chain Management

The evolving supply chain landscape is undergoing significant changes due to globalization, technology, and shifting consumer expectations. Companies are now adopting integrated and digitized systems. These systems not only boost efficiency but also offer real-time insights. This evolution extends beyond just technology; it fosters collaboration among stakeholders.

Today’s supply chain trends show a move from a fragmented view to a more comprehensive approach. Organizations understand the interconnectedness of different functions. They prioritize transparency in product origins, responding to consumer demands for sustainability.

Adopting sustainable practices is becoming more common as businesses aim to reduce waste and embrace circular economy principles. Technologies like blockchain, IoT, and AI are transforming supply chain operations. These advancements in logistics facilitate real-time tracking and autonomous vehicles. They significantly cut labor costs and enhance operation visibility.

In procurement, companies are rapidly integrating AI and intelligent automation to boost efficiency. As you navigate the current supply chain trends, consider the importance of ethical sourcing and sustainability. The future of the supply chain industry will focus more on agility and responsiveness. It will require adapting quickly to market changes while delivering outstanding customer experiences.

Key Drivers of Change in Supply Chain Management

The landscape of supply chain management is undergoing a significant transformation. Understanding the key drivers of these changes is crucial for businesses aiming to adapt. Rapid technological advancements are at the forefront of these shifts. Artificial intelligence (AI) has made substantial strides, with 85% of manufacturing companies adopting AI solutions. This trend is expected to have a profound impact, with 45% of companies predicting significant changes in their supply chain management.

Emerging trends highlight a shift towards prioritizing visibility and efficiency. A remarkable 55% of organizations now view supply chain visibility as a top business priority. This focus is driven by the need to enhance U.S.-based manufacturing and navigate operational challenges. Geopolitical instability and rising raw material costs are seen as critical threats by 71% of businesses for the upcoming year.

The rise of the Internet of Things (IoT) brings both opportunities and challenges. By 2030, over 25.4 billion IoT devices are expected to be in operation, facilitating better data collection and real-time decision-making. This technology has the potential to revolutionize supply chain management. Companies are increasingly turning to digital supply chain analytics and visualization platforms. Approximately 31% are implementing these technologies to improve efficiency in product development.

This combination of technological, economic, and consumer-driven factors is reshaping the supply chain landscape. Organizations must continually reassess their strategies. Investing in advanced technology, ensuring operational resiliency, and adapting to market demands are key steps towards navigating today’s complex supply chain.

Advanced Automation and AI Trends in Supply Chain Management

In the realm of supply chain management, advanced automation and AI technologies are transforming the landscape. These innovations signify a pivotal shift in how companies manage logistics and inventory. With AI logistics integration, firms can streamline their operations, ensuring efficiency and agility.

Integration of AI in Logistics

AI has become crucial in logistics operations. Through machine learning and predictive analytics, organizations can significantly enhance delivery routes and supply chain visibility. The effect of AI on inventory management is profound, as companies increasingly depend on data-driven insights for demand forecasting. This enables businesses to predict stock needs accurately, minimizing the risk of stockouts and waste.

Impact on Demand Forecasting and Inventory Control

Traditional demand forecasting methods often fail in today’s fast-paced market. AI technologies are changing this by enabling more precise decision-making. Companies can expect a 50% reduction in stockouts with AI-driven forecasting. This results in higher customer satisfaction and improved profitability. As supply chain automation trends advance, firms that adopt these technologies will be better prepared to manage market fluctuations and optimize inventory control.

The Role of the Internet of Things (IoT)

The Internet of Things (IoT) is revolutionizing supply chain management. It offers enhanced visibility and data-driven insights, leading to better decision-making. With the rapid growth of IoT devices, businesses now have access to real-time data. This data enhances operational efficiency and adaptability.

Growth of IoT Devices by 2030

Experts predict that IoT devices will exceed 25.4 billion by 2030. This surge will improve connectivity across supply chains. IoT devices will enable companies to monitor parameters like location, temperature, and humidity in real-time. This will provide visibility previously unimaginable, allowing for quick strategy adjustments and operational tweaks.

IoT in Warehouse and Fleet Management

IoT is transforming logistics in warehouse and fleet management. In warehouses, real-time inventory tracking prevents overstock and stockouts, ensuring a balanced supply. IoT’s impact on fleet management is equally significant, optimizing routes and tracking maintenance. Sensors and RFID tags provide continuous data streams, enabling proactive responses to transportation issues.

This level of insight not only cuts down delivery times but also supports agile and resilient supply chains. Such chains can effectively navigate disruptions, ensuring operational continuity.

Supply Chain Resiliency in an Uncertain World

As global challenges persist, the need for robust supply chain resiliency strategies grows. Businesses must swiftly adapt to disruptions. Diverse sourcing and technology integration are key to navigating uncertainty.

Strategies for Managing Disruptions

Today’s organizations employ several strategies to tackle disruptions:

- Diversifying supplier bases to reduce dependency on single sources.

- Investing in advanced analytics to predict potential supply issues.

- Establishing contingency plans to respond swiftly to unforeseen circumstances.

- Applying process automation technologies to enhance efficiency across operations.

Pfizer Global Supply Organization, with over 30,000 colleagues, emphasizes a unified language for streamlined communication. Machine learning and predictive applications help anticipate supply challenges, underscoring the role of agility in supply chains.

Importance of Agility and Flexibility

Agility and flexibility are crucial for success in the current supply chain environment. Companies that focus on these areas can adapt quickly to market changes. Data shows that 79% of consumer products and retail firms are broadening their supplier networks, and 71% are investing in local strategies.

With CEOs increasing investments in disruption detection and innovation, it’s essential for organizations to build resilient frameworks. A culture of continuous improvement helps businesses maintain order fulfillment amidst uncertainty.

Shifts Towards E-Supply Chain Management

The transition to e-supply chain management marks a pivotal change in business operations. It emphasizes the digitization of processes and the use of data for better decision-making. As companies embrace technology, digital supply chain analytics become crucial for improving operational visibility and efficiency.

Digital Supply Chain Analytics

Businesses are increasingly adopting advanced analytics tools, with about 60% now using them. These tools enhance monitoring and decision-making capabilities. With real-time data, optimizing inventories becomes easier, allowing for a quicker response to market changes.

Benefits of Electronic Supply Chain Management

Implementing electronic supply chain solutions offers numerous advantages. These include:

- Cost savings through optimized working capital.

- Improved supplier relationships by streamlining procurement processes.

- Enhanced risk management capabilities utilizing sophisticated technologies.

- Increased agility and transparency across supply chain operations.

- Stronger innovation and collaboration with suppliers to achieve sustainability goals.

Supply Chain Trends: The Need for End-to-End Visibility

End-to-end supply chain visibility is now a top priority for companies aiming for operational excellence. A survey of over 300 supply chain executives revealed that 64% plan to invest in visibility first. Pursuing *supply chain transparency trends* is vital for spotting inefficiencies and reducing risks.

Technological advancements, like IoT and AI-driven analytics, bring real-time insights to your supply chain. These tools enable proactive management, helping you tackle small issues early. This proactive stance is crucial for improving supply chain visibility and reliability.

There’s a growing need for a holistic approach that covers the entire supply chain. This approach not only adds value for customers but also encourages better collaboration among stakeholders. *Enhancing supply chain visibility* through a unified framework leads to better decision-making and stronger resilience.

- Automation in production and warehousing is set to increase, making operations smoother.

- Transportation management systems will play a bigger role in creating efficient supply chains by optimizing routes and cutting costs.

- Companies are shifting from just-in-time to just-in-case inventory strategies, blending predictive analytics with human expertise.

As supply chain management evolves, focusing on end-to-end visibility is crucial for quick responses to challenges and higher customer satisfaction. Embracing these transparency trends is essential for success in the future of supply chain management.

Cloud-Based Solutions and Their Impact

In today’s fast-paced supply chain world, cloud-based solutions are crucial for business operations. The growth of cloud technology in supply chains is expected to hit $40 billion by 2027. This shows a clear move towards more agile and efficient systems. Cloud computing lets organizations integrate their operations smoothly and react faster to market changes.

Cloud Technology Growth Projections

Cloud computing is becoming key in supply chain management, allowing businesses to centralize operations and cut costs. It also boosts scalability. With better visibility across the supply chain, companies can manage data more effectively. This helps tackle issues like sustainability and regulatory compliance.

Companies like General Electric and Walmart are quickly adopting cloud solutions. They’re using Amazon Web Services and real-time inventory tracking to improve their supply chains.

Benefits of Cloud Solutions in Supply Chain Management

Cloud solutions bring big advantages to supply chain management. They make operations more efficient by providing accurate data analytics. This leads to better operations and communication.

Companies save money by using fewer software tools, which simplifies logistics. Cloud platforms offer flexibility and real-time visibility. This streamlines decision-making and encourages collaboration across the network. It sets your organization up for future growth.