Last Updated on December 13, 2025

Continuous improvement is a simple, practical way to lift your daily output without big overhauls. You get small, steady changes that cut friction and help you finish work with less stress.

This Lean-inspired approach borrows tools like PDCA, Kanban, and quick feedback loops to make hidden steps visible. You will spot where your process adds value and where processes slow you down.

Use these ideas to build a personal culture that helps your team and your business move faster. With clear data and short experiments, you keep changes honest and focused on quality in operations, services, and products.

Key Takeaways

- Small tweaks beat big overhauls for steady gains.

- PDCA and simple tools help you test and measure results.

- Translate factory Lean ideas to your calendar and routines.

- Focus on processes that cut rework and speed delivery.

- Build a culture that supports your team and business goals.

- Invest a little effort now for compounding returns in focus and quality.

Why continuous improvement matters for your daily efficiency

Small, steady tweaks to how you work stack up into major daily gains over time. When you treat your day like a short experiment, tiny changes reduce waste and make flow clearer.

Collect light-touch data — lead time, cycle time, throughput, error rate — and you’ll spot where the process drags. Quick feedback from peers or your own end-of-day notes helps you test fixes fast.

A supportive culture lowers the bar to try a new habit. Whether you’re an individual contributor or part of a larger team, involving employees or collaborators creates buy-in and better results.

- Favor low-risk experiments you can run this week.

- Focus on customer value so changes align with business outcomes.

- Watch simple signals (cycle time, error rate) to know what works.

Apply basic management ideas to your routine. Small investments in clarity and feedback drive faster delivery and higher quality across your work and organization.

Kaizen and the continuous improvement process in plain English

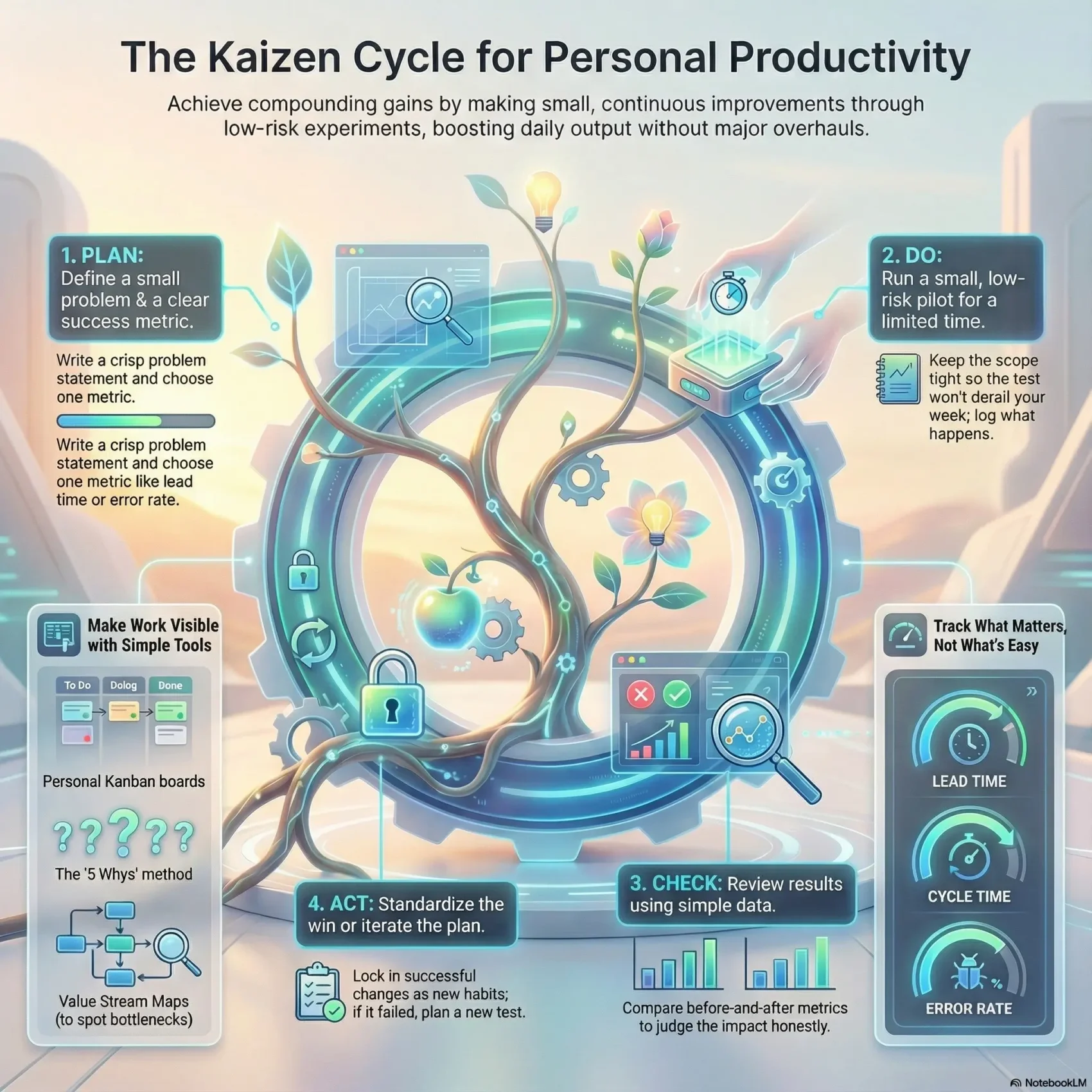

Kaizen asks you to make one modest tweak and measure what follows. It’s a low-friction approach that turns your day into a series of small experiments. You try a tiny change, collect simple data, and decide to keep or adjust the idea.

From factory floors to your calendar: Lean teaches you to chase value and cut waste. Apply that by mapping a task, spotting friction, and removing the smallest block first. Repeat what works.

Incremental changes vs. big overhauls

Pick incremental changes when risk and effort should stay small. A quick test proves value before you scale. Large redesigns can stall momentum and create resistance.

- Plan: pick one hypothesis and define success.

- Do: run a short pilot with clear boundaries.

- Check: use simple metrics and honest data.

- Act: standardize the win or iterate again.

Capture knowledge from each run so your next decision is faster and smarter. Treat your routine as a living process and rely on facts, not mood, to guide change.

Core Lean principles you can use today

Identify the one outcome your customer cares about and let that guide your day. Use that outcome to decide what to keep, cut, or fix in your task list.

Focus on value and cut waste (Muda, Mura, Muri)

Lean centers on value and removes three wastes: Muda (non-value work), Mura (unevenness), and Muri (overload).

Map these to email, meetings, and routine tasks to spot time drains and quality risks. Visual tools like Kanban make bottlenecks obvious so you can act fast.

Empower yourself with small, sustainable improvements

Small changes win over time. Pick tiny experiments that fit your bandwidth and measure results with simple data.

- Define value for the day and prune non-essential work.

- Write one-sentence experiments with a success metric.

- Turn wins into standard work so they hold up under pressure.

- Choose solutions that cut rework, protect focus time, and boost predictable delivery.

“Make value visible, reduce waste, and standardize what works.”

Map waste to your work: spotting time, energy, and quality drains

A quick map of where you lose time, energy, and clarity shows exactly what to fix first. Use a simple sketch of your day or week to track task handoffs, waiting, and repeated steps.

Common personal wastes: context switching, waiting, rework

Context switching steals focus and lowers output. Waiting on approvals or replies creates idle gaps. Rework costs attention and morale.

You’ll identify your biggest drains and quantify them with a short audit. Note each interruption, response wait, and redo for two workdays.

Simple time audits to find bottlenecks

Collect just enough data to see patterns without turning measurement into busywork. Timebox tracking to chunks of 15–30 minutes.

- Record where you switch tasks and how long approvals take.

- Batch repetitive items and protect deep-focus blocks.

- Replace vague requests with clear agreements to cut rework.

“Reduce waiting and handoffs to boost flow — your day will feel easier and more predictable.”

Run a PDCA cycle for personal productivity

Run a tight PDCA loop to turn one small bottleneck into a testable habit. The PDCA cycle keeps your improvement efforts evidence-based and low risk. You’ll focus on a single problem, try a narrow change, and use simple results to decide the next step.

Plan: define the problem, customer, and outcome

Write a crisp problem statement and name your customer — that might be you, your manager, or an external client. Define the desired outcome and one metric that proves success, like lead time or error rate.

Do: pilot a small change with clear boundaries

Pilot a time-bound, low-risk change. Keep scope tight so the test won’t derail your week. Log start and end times and note blockers.

Check: review results using basic data

Use light data — cycle time, error rate, or on-time delivery — to judge impact. Compare before and after and look for side effects that matter to your goals.

Act: standardize what works, iterate what doesn’t

Lock in successful steps as standard work and train yourself or a teammate to keep them. If results fall short, run a new Plan with improved hypotheses.

- Why this works: Short cycles lower fear of change and build momentum.

- Align goals: Tie each experiment to a meaningful outcome so every cycle moves you toward results.

- Get feedback: Involve a stakeholder when useful to tighten the loop and increase adoption.

“Small, measurable cycles make process changes safe, fast, and repeatable.”

Tools that make Kaizen visible: Kanban, 5 Whys, and value stream mapping

Make your invisible work visible with three simple tools that expose bottlenecks quickly.

Personal Kanban: limit work-in-progress to boost throughput

Set up a visible backlog, WIP limits, and clear done criteria. Teams that added Kanban with tight WIP limits often visualized blockers and doubled throughput in days (Aerosud is one example).

Why it helps: WIP limits cut context switching and show where the process stalls so you can fix the system, not push harder.

5 Whys for root-cause clarity on recurring issues

When a task repeats or a problem reappears, ask “Why?” five times. Keep the questions focused and stop when you reach a root cause.

Result: You treat causes, not symptoms, and find small solutions that hold up over time.

Value stream map your morning routine

Map each step, wait time, and handoff to expose delays and rework. Use lightweight data from your board—lead time and cycle time—to decide what to remove or automate.

- Keep boards simple and define columns clearly.

- Revisit WIP limits weekly and tune by the data.

- Turn insights into solutions: remove steps, automate handoffs, and standardize start-of-day checks.

“Make value visible, reduce waste, and standardize what works.”

Data that drives better results without the headache

A few well-chosen metrics give you direction without adding reporting busywork. Use simple measures to see where your day stalls and what moves your goals forward.

Track lead time, cycle time, and error rate in your tasks

Pick three core metrics — lead time, cycle time, and error rate — that tell the story of your work. These capture speed, flow, and quality without extra admin.

Also include throughput as a check so you know volume alongside pace. Define each term clearly so your measures stay honest.

Create a lightweight dashboard you’ll actually use

Design one-screen views that flag bottlenecks and quality dips. Keep charts simple: trend lines for lead time, a bar for cycle time, and a red/green marker for error rate.

Automate capture from your calendar or Kanban board so tracking fits your process naturally. Run a short weekly review and let the numbers trigger decisions, not meetings.

- Keep it small: three metrics that map to your goals.

- Stay stable: define terms, avoid vanity stats.

- Act on signals: each chart should suggest a next experiment.

“Use light data to prove what works and to guide the next cycle.”

Build a culture of continuous improvement in your own routine

Make small rituals the engine of steady gains. Start with a tiny set of repeatable actions that focus your day and surface what to change next. These habits keep progress visible and reduce decision friction.

Daily rituals: stand-ups with yourself and end-of-day retros

Try a 5-minute morning stand-up to set a clear priority and a quick end-of-day retro to capture a single learning.

Record one metric about your process each day and note blockers. This turns vague work into data-driven decisions.

Celebrate micro-wins to sustain momentum

Design tiny rewards for milestones so motivation stays high during longer work. Share short wins with a peer or your team to build trust and buy-in.

- Log experiments and insights in a personal knowledge file.

- Request timely feedback from a peer or customer and turn it into clear next steps.

- Review your processes on a simple cadence so changes stick.

For tips on aligning rituals with reviews, see performance reviews and rituals. This helps employees and the business treat process change as normal, not extra work.

Implementing continuous improvement when you’re part of a team

Begin with a single project or process where changes will be visible in days. Pick a small pilot that has a clear scope and visible value so your team can test without risk.

Align personal goals with team and organization objectives. Match one or two of your daily targets to the team’s priorities. That way your experiments move the organization forward, not just your to-do list.

Train and equip the team. Run a short session on PDCA or Value Stream Mapping, and give simple templates so employees can run experiments confidently.

Feedback loops with peers and customers

Establish tight feedback cycles: quick peer check-ins and brief customer reviews. Use short surveys or a five-minute demo to catch issues early and keep value aligned.

- Define success metrics before the pilot starts.

- Empower employees to try small changes and report results.

- Use lightweight tools to capture feedback and next steps.

- Present concise results to management to secure buy-in for scaling.

Standardize wins and weave them into operations. When a solution works, create a short checklist so the change survives handoffs, vacations, and growth. This pragmatic approach to implementing continuous improvement keeps the work practical, fast, and tied to real results.

Lean and Six Sigma strategies for knowledge work

Apply a blend of flow-focused Lean thinking and data-led Six Sigma to reduce variation and raise the quality of your outputs. These methods work well for tasks that feel unpredictable or error-prone.

Reduce variation in outcomes with simple checklists

Use short checklists to catch common mistakes before work ships. A three-step pre-delivery list prevents obvious errors and saves rework.

- Why it helps: checklists lower mistakes without adding bureaucracy.

- When to use: before client handoffs, releases, and key reviews.

- Tip: see practical checklists for complex projects for examples you can copy.

Standard work for recurring tasks

Document short, repeatable steps for core tasks so you stop reinventing the wheel. Standard work stabilizes outcomes and makes training faster.

Use lightweight data — a couple of metrics — to verify that the new standard actually cuts errors and speeds flow.

“Pair Lean to strip waste and Six Sigma to reduce variation; the result is predictable, measurable progress.”

Overcoming common challenges in implementation

You can lower friction quickly by shrinking experiments and naming one obvious first step.

Resistance to change is normal. Start by making the first action trivial: a five-minute test or a one-click habit. That reduces fear and shows early value.

Resistance to change and how to lower the bar

Make wins visible and share short results with stakeholders. Use quick wins and timely feedback to build trust.

- Shrink scope so the first test takes days, not months.

- Map who is affected and tailor simple messages to each group.

- Celebrate micro-wins to keep employees engaged and curious.

Training yourself on new tools without overwhelm

Teach just-in-time skills and one-page cheat sheets. Focus training on the exact steps people will use that week.

Define the real problem you’re solving, pick one metric, and collect minimal data to prove impact. That keeps your efforts practical and fast.

“Lower activation energy, show quick results, and make learning tiny.”

Finally, keep rituals short and repeatable so the new process fits daily work. Small, measured steps help your organization and management adopt lasting solutions with minimal extra effort.

A practical 30-day plan to implement continuous improvement

Start with a sharp, 30-day plan that turns one small bottleneck into measurable gains. Pick a pilot you can run in days, not weeks. Teach core tools—PDCA, Kanban, and the 5 Whys—so the team knows how to test and learn.

Weeks at a glance: focus, experiments, and review cadence

- Week 1: Define one problem, one customer, and one clear metric. Plan a tiny experiment you can finish in days.

- Week 2: Do the test with tight boundaries. Track light data and log observations in a simple notebook.

- Week 3: Check results versus goals. Compare data and decide what to keep, change, or drop.

- Week 4: Act: standardize wins, write a short checklist, and pick the next small experiment or project.

Scaling what works across projects and processes

Package results and lessons into bite-size playbooks so others can adopt the same solutions quickly. Use simple success markers—shorter cycle times, fewer errors, more predictable delivery—to judge scale readiness.

Sustained success comes from iteration and keeping changes small and reversible. Finish the month with a repeatable playbook you can reuse quarterly to compound knowledge and results across your business.

Conclusion

Treat one tiny bottleneck as your next experiment and let clear metrics guide you. Use a simple approach: pick one metric, collect light data, run a short test, and decide fast. This keeps risk small and learning steady.

When you focus on value and cut obvious waste, you free time and raise quality. A short PDCA cycle plus a few honest numbers—lead time, cycle time, error rate—helps you choose changes that actually matter.

Remember: continuous improvement lives in habits, not big projects. Standardize wins, keep rituals short, and align your process with team culture so your operations and services get more efficient over time. Your next step is small: pick one problem, one metric, and start your next PDCA cycle today.